Hi Butt...

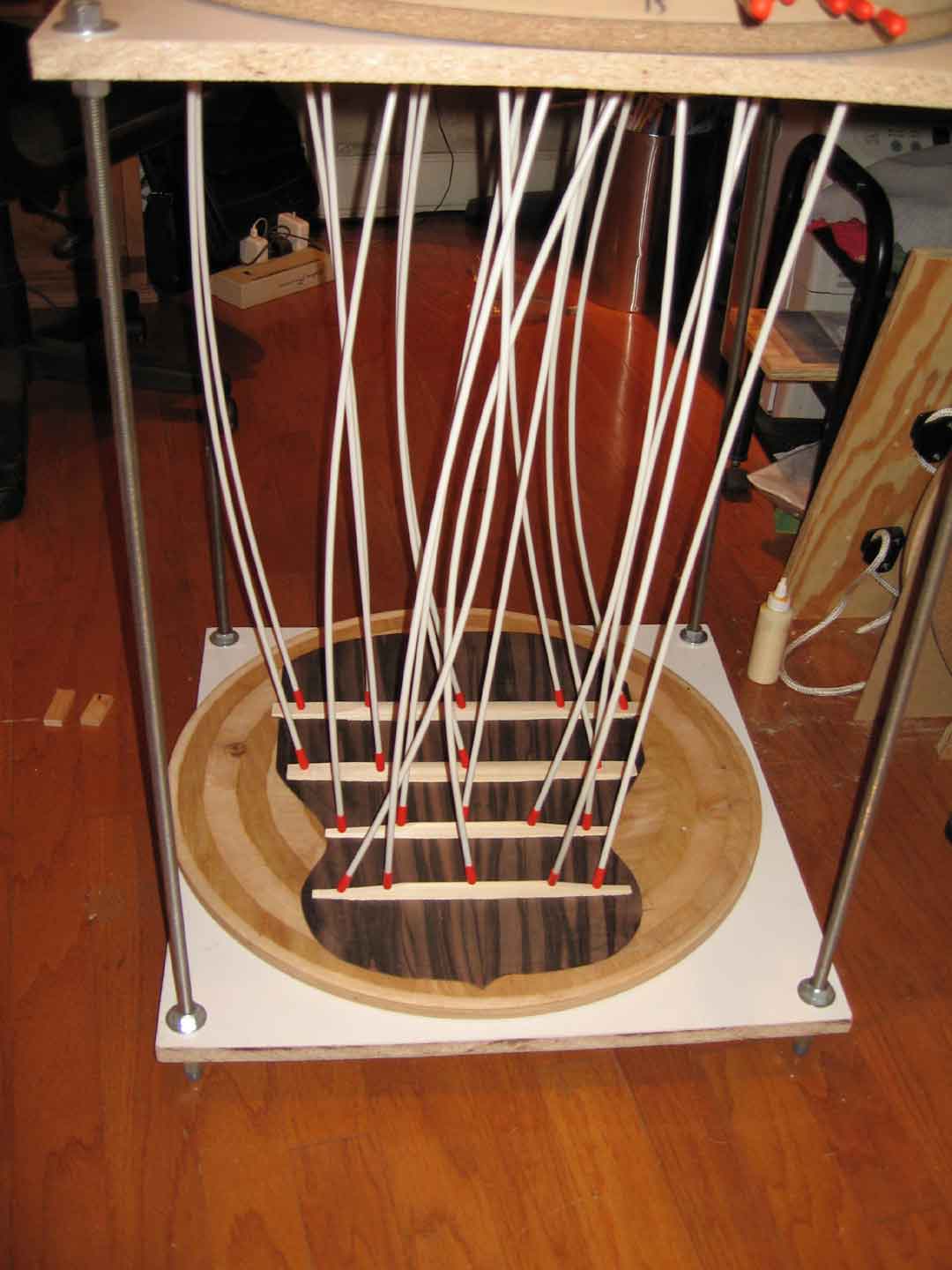

I had followed the Stew-Mac's plan to the tee, and put a go-bar deck as per their instructions. However, by the time I was done it weight a ton, so I built another one, & his time it was a "less-heavy duty" one. Downsizing the threaded rod size, & not using 4 pieces of 2' X 2' for the base (only 2), and it has worked out just fine.

I can say, that the 'height factor' for the rods later turned out to be a bit of a problem, as the rods need to be different lengths to fit in w/ the right tension, when & if you glue your top & back on to the body using the go-bar rack. Add in the thickness of the sanding dishes too. So you see, the lengths of the rods change at different stages of your assembly. Longer, for gluing the braces to top & back, & shorter for gluing top & back to body.

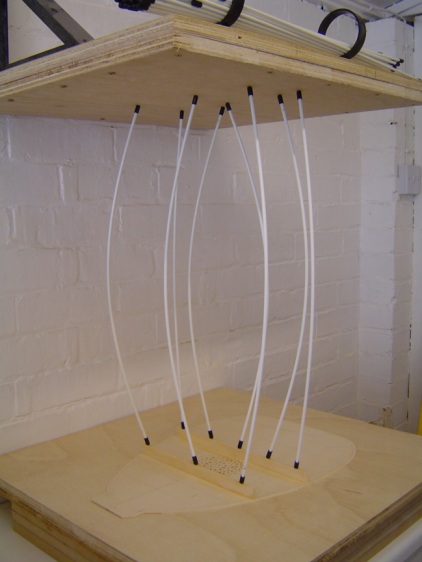

To remedy this, someone had posted a pic of a go-bar deck that was made, so that the top & bottom platforms were adjustable w/ adjustable pipe clamps. This way you can raise or lower the distance in between to accomodate one set of rods. I think Kathy Matsushita was the one who posted some info on this, but I could not find it on her site?

I hope this made some sense to you? It's a little hard to see what I'm talkin' about w/o pics. I am going to still build another one using the pipe clamps, in an effort to...having less rods around for the show!

|